Shipping Nationwide

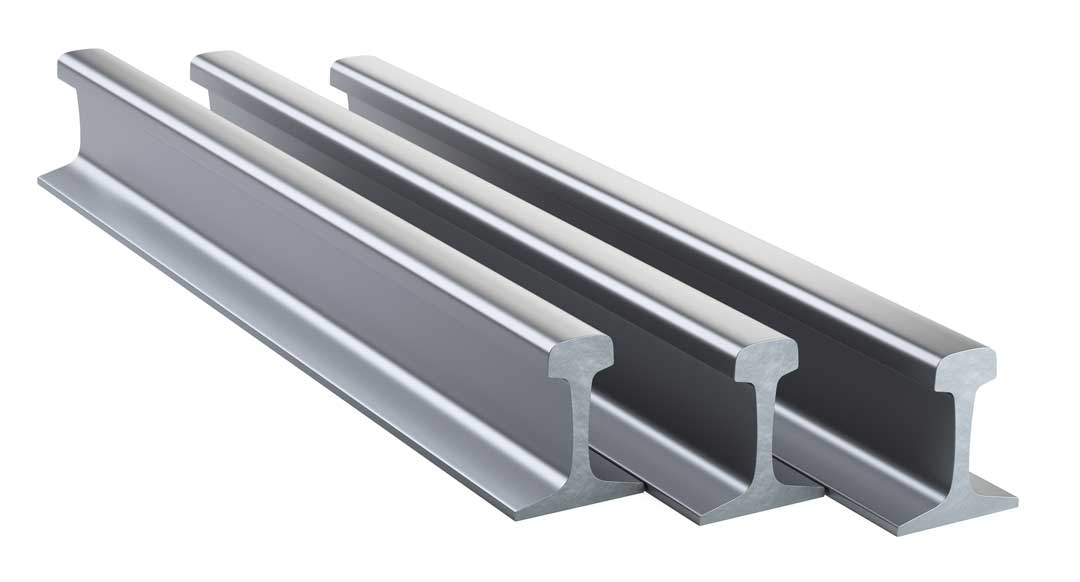

Product Images

Browse through our collection to witness the robust nature and aesthetic appeal of our steel beams, setting the foundation for your projects with confidence and durability.

Shipping Nationwide

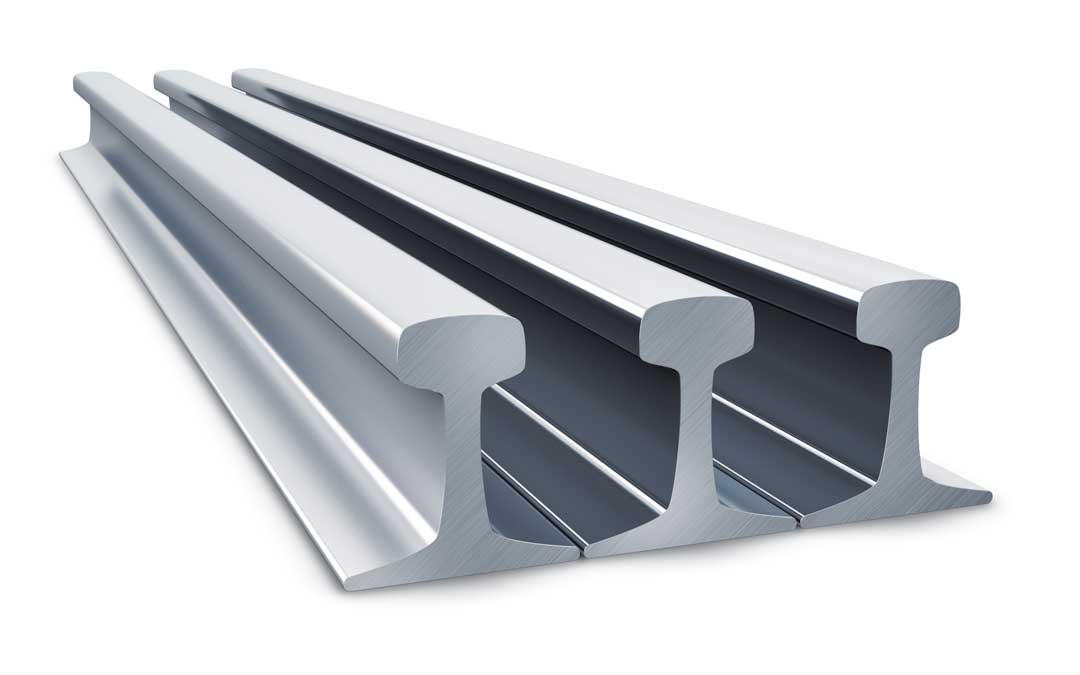

I-Beams or universal beams, are structural steel beams with an “I” shape when viewed from the cross-section. The design of I-beams provides them with significant advantages in construction and engineering applications.

Commonly used for:

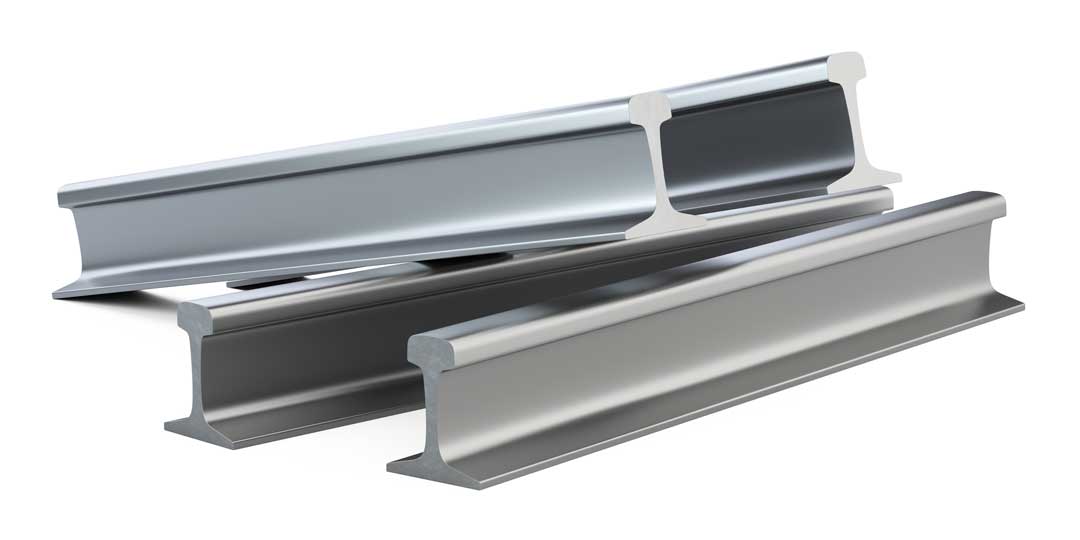

T-beams are a structural engineering element widely employed in construction, characterized by their T-shaped cross-section. The key advantage of T-beams lies in their efficient distribution of load-bearing capacity. The horizontal top flange and vertical web work in tandem to resist both bending and shear forces.

Commonly used for:

Built-Up Beams, also known as composite beams, are structural elements composed of individual steel or timber sections that are assembled and fastened together to form a larger, more robust beam. It combines the strengths of different materials to create a beam capable of withstanding higher loads and spanning longer distances.

Commonly used for:

H-beams, also known as wide-flange beams, are structural steel beams characterized by their H-shaped cross-section. The design of H-beams provides significant advantages in construction due to their optimal distribution of material along the horizontal axis, resulting in a higher load-carrying capacity and resistance to bending.

Commonly used for:

Browse through our collection to witness the robust nature and aesthetic appeal of our steel beams, setting the foundation for your projects with confidence and durability.

Steel beams are essential structural components in the construction of buildings and bridges. Crafted from structural steel, an alloy of carbon and iron, these beams come in various shapes and sizes. Their significance lies in their ability to play a vital role in the load path of structures, efficiently transferring loads from rooftops down to the soil.

Structural engineers carefully select the appropriate steel beam design for each construction plan, ensuring optimal load-bearing capacity. In the framework, steel beams span horizontally between columns, supporting the loads above them.

Steel beams, especially from a reliable I-Beam supplier in the Philippines, serve as integral parts of the skeleton, providing essential support to structures such as residential and commercial buildings, skyscrapers, stadiums, bridges, and even cargo ships.

They carry vertical loads and, in some cases, support horizontal loads, such as those induced by earthquakes. In residential construction, steel beams are commonly used as the main support beam in basements, offering superior strength and the ability to cover significant distances.

Steel beams present various advantages, contributing to their widespread use and preference in various construction projects. These benefits extend across both general structural applications and specific considerations within residential construction.

The durability of steel beams stands out as a key advantage. With inherent strength that surpasses that of wood or stone, these beams can withstand larger loads thanks to an impressive strength-to-weight ratio. Additionally, the recyclability of steel is a notable benefit. The capacity to repurpose steel significantly aids in decreasing construction waste and lessening the environmental impact associated with construction projects.

Specializing in delivering high-quality structural solutions, Linton Inc., a trusted I-beam supplier in the Philippines, offers a range of steel beams designed to meet the demands of modern construction projects. Each type is carefully crafted to address specific requirements, ensuring optimal performance and structural integrity.

I-beams represent a primary category in steel beams with their distinctive I-shaped cross-section. This universal beam finds widespread use in major structures due to its excellent bending capacity under high stress, ensuring it does not buckle under pressure.

H-beams, a variant of the I beam, possess a slightly different cross-sectional shape, featuring a thicker central web and wider flanges. Linton Inc. stands as the leading I-Beam supplier in the Philippines, catering to the intricate needs of the construction industry.

T-beams, characterized by their T-shaped cross-section, serve essential roles in framing, repairs, and roof trusses within the construction industry. With no bottom flange, T-beams exhibit a unique design that, while less versatile than other beams, excels at acting as compression flanges to reduce shear stress vulnerability.

A built-up beam, also known as a compound beam, is utilized when the span, load, and corresponding bending moment necessitate a section modulus beyond the capacity of rolled steel beams. Built-up beams come into play when the depth of a rolled steel beam is limited due to architectural constraints or when additional strength is required.

Selecting the right supplier of I-Beams in the Philippines is crucial for ensuring the success and structural integrity of your construction projects. Among the many suppliers in the country, Linton stands out as a beacon of reliability and excellence.

It is crucial to prioritize the quality of materials when choosing a dependable supplier. Seek a provider that delivers I-beams made from top-tier materials to guarantee both durability and strength. Opting for high-quality materials enhances the lifespan of structures, establishing a robust foundation for your construction endeavors.

Adherence to industry standards is non-negotiable when it comes to structural components. Choose an I-Beam supplier in the Philippines that strictly complies with industry standards, meeting or exceeding necessary specifications and requirements, enhancing safety and stability.

The reliability and competence of a supplier specializing in I-beams can be gauged through their expertise and reputation. Choose a supplier with a well-established history and a favorable standing within the industry. A supplier’s extensive experience signifies their consistent ability to fulfill the varied requirements of construction projects, instilling confidence in their capabilities.

A reliable I-Beam supplier in the Philippines ought to present a wide array of products and services to meet different construction needs. Look for a supplier that not only offers an extensive variety of I beams but also includes additional valuable services. Streamlining the procurement process becomes easier when you have access to a diverse range of products and services from a single supplier.

Linton distinguishes itself as a dependable partner in the Philippines, providing unmatched consistency and exceptional quality in the supply of I beams. Explore the key factors that make Linton the preferred choice in the industry.

At Linton, we prioritize quality assurance. Our products undergo meticulous testing and inspection procedures to guarantee they adhere to the most rigorous quality standards. As a reputable I-Beam supplier in the Philippines, we are dedicated to delivering products that surpass expectations in terms of durability, strength, and overall performance, providing our clients with the assurance that their structures are constructed on a robust foundation.

Linton’s commitment to quality is reinforced by certifications and adherence to industry standards. Our steel beams are certified to meet or exceed the necessary specifications, ensuring compliance with stringent standards. This dedication to quality and conformity enhances the safety and reliability of the structures where our products are utilized.

Beyond being a premier I-Beam supplier in the Philippines, Linton boasts a diverse product range, including various types of metal and steel products. From steel plates to sheets and coils, we offer a comprehensive selection to cater to the diverse needs of construction projects. Our commitment to providing a one-stop solution sets us apart in the industry.

Here at Linton, we understand the importance of timely project completion. Our efficient logistics and on-time delivery ensure that your I-beams and other products are delivered when and where you need them. With a streamlined supply chain and a commitment to meeting deadlines, Linton supports the smooth progression of your construction projects.